Lew™ MDI O-Ball Implants

Lew MDI implants offer refinements to address the most common reasons that other mini implants fail to integrate.

The main application for the Lew MDI Mini Dental Implant is the stabilization of a full denture in the mandible and maxilla. The line offers a choice of 2 diameters: 2.0mm for use in the mandible and the dense bone that one can encounter in that region and the 2.5mm which is better suited for the maxilla and softer bone.

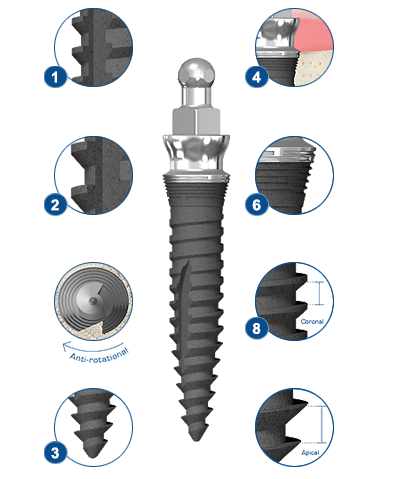

Implant Features:

Collared O-Ball Shown Below

- Optimized Tip for Tactile Feedback

- Platform Switching Collar

- Labyrinth Groove Banding to prevent tissue migration

- Progressive Compression Threading to compress bone and improve implant stability

- Diameters of 2.0 / 2.5mm* & 3.0mm

- Choice of lengths 10, 11*, 13, 15, 17mm

- Choice between non-collared and platform switching gingival collar

- Prosthetic options: metal housings, temporization caps or waxing copings

- Biocompatible Titanium Grade V

- Three sizes of metal housings available

Benefits:

|

Minimally invasive & ideal for narrow ridges Simple 4-step surgical procedure No flap or suturing required Immediate loading in most cases Customized retention & simple chair side prosthetic procedure Designed with Reverse Buttress Threading to resist pull-out forces Designed with anti-rotational cog lock feature |

Lew MDI - Indications & Solutions:

Lew™ MDI is a versatile and minimally invasive system aimed at proving implant solutions in a simplified cost and time effective manner both for the practitioner and the patient.

Lew MDI is not meant as a replacement for conventional implantology but as a complement. The Lew™ MDI Mini Dental Implant system is for the stabilization of a denture in an edentulous mandible or maxilla, replacement of missing laterals, use in narrow ridges or spaces where conventional implants are too large to fit.