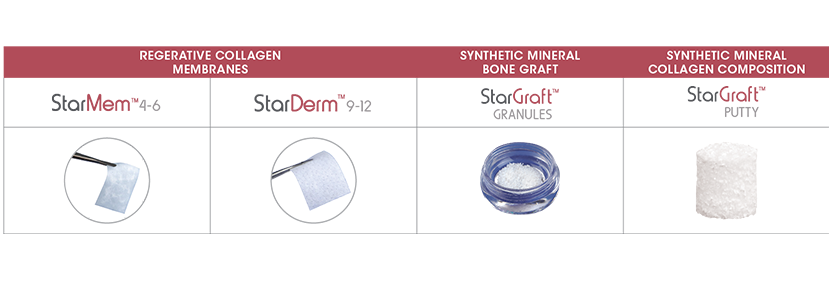

Biologix™ Regeneration Materials

StarMem™ 4-6 Product Features:

- Resorbable in 4-6 months

- Highly purified type I collagen

- Highly biocompatible

- Conformable and repositionable

StarMem™ 4-6 Regenerative Collagen Membrane is a white, nonfriable, conformable membrane matrix engineered from highly purified type I collagen derived from porcine tendon. It is indicated for use in oral surgical procedures as a resorbable material for placement in the area of dental implant, bone defect or ridge reconstruction to aid in wound healing.

StarDerm™ 9-12 Product Features:

- Resorbable in 9-12 months

- Highly purified intact collagen

- Mechanical strength

- Thicker for longer in vivo stability

- Highly biocompatible

- More space maintaining

StarDerm™ 9-12 Regenerative Collagen Membrane is a white, nonfriable membrane matrix engineered from highly purified porcine dermis. It is intended for use in oral surgical procedures as a resorbable material in the area of dental implant, bone defect, or ridge augmentation to aid in wound healing.

StarGraft™ Granules Product Features:

- Synthetic alternative to allografts and xenografts

- Carbonate apatite structure similar

- Moldable putty upon hydration to natural bone

- Osteoconductive

- 0.35 - 1.0mm particle size granules

StarGraft™ Granules Synthetic Mineral Bone Graft is an osteoconductive calcium phosphate-based bone graft material intended for use in oral surgical applications involving bone repair such as augmentation or reconstructive treatment of the alveolar ridge, filling of periodontal defects, filling of defects after root resection or extraction sockets, and elevation of maxillary sinus floor.

StarGraft™ Putty Product Features:

- Carbonate apatite plus Type I collagen

- Moldable putty upon hydration

- Osteoconductive, 3-dimensional structure for bone forming cells

- Mineral particles are contained within the defect site

StarGraft™ Putty Synthetic Mineral-Collagen Composite is a bone graft matrix with an additional characteristic that enables it to become moldable putty upon hydration. It is intended for use in oral surgical applications involving bone repair such as augmentation or reconstructive treatment of the alveolar ridge and for the filling of periodontal defects in conjunction with products intended for Guided Tissue Regeneration and Guided Bone Regeneration.